Austrian Patent

# 113,487

(June 10, 1929)

"Construction

for Creating Wild Brooks & Flow Regulation"

by

Viktor Schauberger

The invention corresponds to a

construction for creating wild brooks and flow-regulation through

the speed of water that is dammed, so that with oriented stones no

destruction may come along the course of the waterpath through the

damming constructs, and to place the central line of the watercourse

in the middle of the stream.

The invention is illustrated in the

drawings; Figure 1 is an example of water-conduction and

damming in the shape of transversely-placed dams.

The dams (1) are hollow and made of

concrete placed and anchored to the ground with suitable anchors

(2), so that they cannot be displaced by the streaming water. The

striations are placed against the direction of the waterflow, upon

which the water runs and along which it will sluice; through this

coursing the water loses the greatest portion of its energy and does

not strike too hard against the placed dams, forcing them out of

place.

The dams can be placed at far or

close distances from each other in the course of the constructed

brook. In order to lay the theoretical middle of the stream in the

midst of the flow in far-off places and also to prevent the

destruction of the river shore through erosion, we will place

constructions by the sides of the flow that will act as dams as seen

in Figure 2. In this figure the dams are indicated by (3),

while the stones are placed at (4) in opposite places. The middle

line of the waterflow (5) runs through them as illustrated.

Figure 3 shows in greater

detail one of such constructs and Figure 4 a transverse cut through

one of them.

The constructions (3) are essentially

triangular-shaped, and are jammed into the soil against the shore so

as to elevate and make the water flow towards a middle point.

The effect made by these

constructions is further illustrated in Figure 4, where the

dashed line (6)-(6) in the transversal cut of the ground before the

construction, which obliges the ground to place itself along the

dashed line because of the disturbed waterflow.

The oriented stones are placed

between the constructions (3) and this builds a zone of still water

close to them, next to the shore, and also serves the purpose of

directing the waterflow and to protect the shores from erosion

through water (Figure 3). The full line (5) indicates the

middle of the stream in the corresponding construction, while dashed

line (5?) indicates the middle line in the brook under the influence

of the constructs.

Figures 1-4

Austrian Patent

# 122,144

(April 10, 1931)

"Artificial

Channel for Transporting Logs"

by Viktor Schauberger

The transportation of logs and other

varied loads through water channels and other artificial channels,

though its low cost makes it competitive against other

transportation means, suffers under the condition that when moving

along the water flow some logs, especially in curves, tend to remain

stuck and in this way sop the following logs, diminishing the

general speed of the transport. This is especially true for hard and

dense woods that remain at the bottom of the channel and move

forward very badly.

It is known that the speed displayed

by logs in water channels is greater than that of the waterspeed; at

those places the speed of the logs greatly surpasses that of the

transporting medium and it is seen from Figure 1 that the

floating log creates a frontal wave (0) as it moves.

While lighter wood (Figure 2)

floats witho0ut problems, heavier wood sits at the bottom of the

channel (Figure 3) and remains stuck; therefore the water

impulse in channels is not enough to produce the usual motion

through sliding without external water spillage.

The invention pertains to a discovery

that corrects these evils, namely the elimination of water spillage

through the implanting of wedges made of wood and the transportation

of hard and dense woods through sliding in the channels.

The speed of the water depends

overall also on its sliding over the channel walls; in the usual

slanted channels, this important factor is eliminated because of

their construction.

The channels? cross-section is not

semi-circular or straight, but rather, as seen in Figures 2, 3

and 4, semicircular (B) with an added semicircular bottom (U)

which radius is half that of the upper portion (B), so that along

the line (E)-(F) in Figures 2 and 3, a resting portion

(L) can be included; the internal wall at the upper semicircular

portion is of striated material (unretouched cement, directionally

nailed wood, etc.), and the underlying portion (U) of a sliding

material (flattened cement, polished wood, etc.), so that the water

speed in the lower region (U) is much greater than in the upper part

(B).

This causes at once the sinking of

water in the middle of the stream (Figure 4); in practice,

when a weight falls a certain distance, the water striking against

the striated channel walls moves further, maintaining the mass (H)

in the midst of the flowing medium by means of the polished

underzone (U) that displaces the water faster.

When transporting floating light

woods (Figure 2), this will not cause any disorder in the

flow of water, for the underzone (U) will run faster than the upper

zone (B); in this manner it will not be necessary to build dams

outside the channel to contain the spilled water.

From light woods we expect little

problem, but with hard and dense wood we must expect it to sink

deeper and to advance with difficulty, so that this kind of wood

will sink itself into the faster-running underzone (U), and advance

in this fashion as if advanced by a transporting band.

When transporting hard and dense

woods (Figure 3), different laws come into play; the wholly

submerged log (H) is entirely in the faster-running water, so that

the pressure upon (E) and (F) of the submerged sliding skids (L)

makes them enter into action, for this time the usual impulse of

water is not enough to make the log (H) advance. If these means are

not added the logs must remain stuck in the bottom of the channel.

In opposition to the present (1931)

transportation of hard wood through channels built with hardened

materials, the dense and hard wood will be transported by

doubly-concave channels with wall built with lighter materials, for

they are not obliged to withstand such heavy loads. In curves, where

the moving wood is obliged to follow them we can, through the proper

construction (Figure 5) of the channel, with only a one-sided

channel wall, make the log move towards the outside where it will be

held by the running water along the curve; if need be, we can add

sliding skids (L) as seen, which can be improved by the addition of

wheels.

Figures 1-5

Austrian Patent

# 134, 543

( August 25, 1933 )

"Conduction of

Water in Tubes & Channels"

by Viktor Schauberger

This invention relates to the

concentration of flowing water within polished conduits (pipes),

channels and tubes, so as to increase the amount of flowing medium

passing through them.

The inventor has discovered that when

a certain kind of turbulence happens in flowing water, then a

temperature difference takes place within it, producing also a

difference in the water speed, and that this happens especially in

Waltz-like flows.

It is known that to hinder

sedimentation, water channels and tubes are built of circular

cross-section, so that the flowing medium may drag with itself any

sediments left; this is to provoke a screw-like movement of water so

that it may attract all particles in its path.

This invention pertains to a further

development of this principle, to drag sedimented masses with moving

water.

The main idea of this invention is

seen in Figure 2, where the usual path of flowing water (4)

is detoured by a wedge-shaped device into a different way (5).

Figure 5 shows an improvement

of this idea by adding striations (6) to the wedge placed on the

inner wall of a channel or tube.

In Figure 1, we see the wedges

grouped (2)-(2?)-(2") in groupings of three, and producing as a

result the screw-like flow (3)-(3?)-(3") through the internal

portion of the conduit (1).

This makes the waterflow concentrate

at the center of the tube, with a concentrical motion, dragging

along any particles left upon the walls.

Figure 3 also shows, in a

lateral view, how the normal water path (4) is changed to a

concentrical one (5), to generate a concentrical flow in the flowing

medium.

Figure 4 shows how open

semi-circular channels can also be adapted to the same purpose.

Figures 1-5

Austrian Patent

# 136,214

(January 10, 1934)

"Installation &

Correction of Flow in Draining Channels by a Contention &

Stabilization of Dammed Water"

by Viktor Schauberger

This invention pertains to an

installation related to the conduction and regulation of flwo in

water channels by contention and stabilization in higher levels by

means of dams integrated into them that depend on the outer

temperature of flowing water and mixing at will of light and hard

water conducted out of the basin by its own means, with which it is

convenient to direct the outer-flowing hard water for cooling the

layers of lateral walls of the dam of the basin, as will be shown

herein.

It is known that for the management

of water channels in all channel-building techniques that a weighty

argument, such as water temperature in earth vessels and air

temperature as the temperature difference between still and running

water, is always left out; and it is also known that the temperature

differences between two or more watercourse modifies their speed

when they mix.

So far, only through artificial

constructs in dams, the naturally-built water channels running

underground or only through ramparts (where only hard water with a

temperature close to +4 degrees C. comes out), or by means of

aquaducts placed atop dams (through which channels of only light

water of high temperature flows), find obstacles in their coursing

through the channel and cause erosion in their shores.

However, through a channel can also

flow those waters with the corresponding right temperature, so that

they can be directed to damming the water masses and to diminish

their forward-going impulse or to increase their speed and their

forward-going impulse in the willed direction. We can also affect

works of shore-correction just by correct regulation of water

temperature and also through the emplacement of dams which capacity

of endurance is directly proportional to the amount of water dammed

and also to achieve an obstacle-free flow of water. The widening of

the channel through the emplacement of stones or elimination of same

(ballast banks) and the elevation of the shore, especially in

curves, can be made by the corresponding directing, but usually

provokes a counterflow that erodes the whole work. Through several

devices that will be explained here, it is possible to steer both

light and hard waters, corresponding to the temperatures of each and

also to the related fall of temperature, so that by means herein

explained each water will run along its own level.

At the same time with the regulation

of the waterflow, it is necessary to install in the construction of

the closing dam of the basin, pipes that will effect the cooling of

the dam?s pores through the sides of the dam by means of small

watercourses directed through the materials.

Then as temperature diminishes, the

water within the dam?s pres loses its attraction for dissolving salt

and other stuffs, until it reaches its balance point at +4 degrees

C, at which its capacity for dissolving is the least and the

filtration in the dam?s wall is the strongest. So far, it is then

when the light water infiltrated in the wall for cooling will go

inside the materials through the pores; in this moment, the channel

walls close to the dam are filled with hard water at a temperature

of +4 degrees C, which lose their salts into the neighboring ground

as they move, creating in a few weeks of impregnation a further

barrier against erosion, and if frost comes, it will also contribute

to the strengthening of the walls

In the drawings we find a further

explanation of a device for this kind of installation; it is seen in

transverse cut in Figure 1 and in upper view in Figure 2;

at Figure 3 we see an internal cutaway view of the apparatus

for steering water.

For the sake of regulating the flow

of cold hard water and warm light water, ground nozzles (O) are

placed in the dam chamber (K) of basin (B) on both sides of the dam,

which doors are activated through a floating device (G) that moves

because of temperature differences. The pipes (W) of the nozzle (O)

lead up to the upper-placed potion (K1) where the flow conduits

(U1)-(U2)-(U3), which are closed through gravity-activated valves

(V1)-(V2), branch in different heights from the upper-going pipe

(W), and that lead further into the lateral wall of the basin,

spreading out there into the corresponding casts. At the foot of the

dam?s internal wall will be conveniently placed the outstanding

portion (K2) to produce a whirling and better mixing of the water

masses flowing over the wall. The door (T) in the nozzle (O) cleaves

the soil of the water channel, sinking itself into it, and is

connected vertically by means of a shaft (F), coursing inside the

dam?s wall (H), with the floating device (G) that is built as a

submersible bell. In the illustrated wall (H), we find at different

heights over the ground-nozzle (O) tube-shaped outlets (A) that

communicate with the tube leading upwards to the bell (G) and allow

the automatic emptying of the water basin.

When the pipe (W) is allowed to fill

through the opening of door (T), it will allow a communication

between the pipe and the basin that will release pressure from door

(T) unilaterally, and in this fashion allow its free motion upwards.

The door (T) should be built of wood to allow the free motion of the

bell (G) when the right water level is attained. The floating bell

(G), which connecting shaft (F) goes downward, can in this fashion,

and because of the only motion it is allowed to make, float upwards;

the bell (G) in Figure 3 has an air valve (P) through which opening

can be introduced pressurized air within, so that the door (T) will

be activated at once. Through both an open end and with the

outstanding tube (R), we can create a flow of water through the

floating up or down of the bell.

When the diving bell is fully sunk,

without any air margin, it acts to totally close the valve; and when

we inject air within it, then raises to allow the opening of door

(T).

In normal work, the atmosphere

imprisoned within the bell (G) is equal to the usual atmospheric

pressure and thus the outer temperature of the environment acts as a

control; depending on the imprisoned air volume within (G), the

outer temperature will make t raise or descend, allowing the

steering of door (T) upwards, so that the mass of hard water that

will be conducted through the nozzle (O), the pipe (W) and the flow

tubes (U1)-(U2)-(U3), will depend on the changes of outer

temperature; the light water flows over its own flowing plate placed

atop the dam?s crown in the basin.

The interpenetration of light and

hard waters can be improved through the construct (K2) placed at the

foot of the dam?s inner wall, and also because of the fact that hard

water falls vertically while light water does so spirally through

flow tubes (U1)-(U2)-(U3), so that during their fall they will

combine.

Through heating from the sun?s rays,

the diving bell (G) will further raise the door (T), and through the

channel a greater percentage of hard water will be eliminated with

respect to the light water that flows over the dam?s top, and

instead with cooler external temperatures the door (T) will remain

either totally or almost totally closed and the channel will only

conduct warm overflowing liquid.

For a better mixing of light and hard

water flowing over the dam?s top, I have placed the flow tube (U2)

in the lower part of the dam?s wall (K), so that it or (T) will

prevent the water from overflowing the basin?s level.

The water flowing within the dam?s

lateral walls contributes to further cooling them and also to leave

deposited salts and other stuffs that it loses when reaching a

temperature of +4 degrees C.

By opening the flow tube (U3) atop

the dam?s wall, the upper portion of the dam can be affected as

indicated in the former paragraph; the welfare of the dam?s wall (in

all its portions) needs this process of impregnation so that its

pores are closed and no filtration may happen.

The upper plate (M) serves to allow

the overflowing of light water and to separate the hard water

flowing through the conduit (U3), thus helping to further its

endurance.

Figures 1-3

Austrian Patent

# 138,296

(July 10, 1934)

"Water

Conduction"

by Viktor Schauberger

This invention pertains to a further

improvement of the tubes and channels shown in Austrian Patent #

134,543, where the water flowing within a conduit is led into

the middle of the pipe to force it to effect a circular motion, as

seen in the forementioned patent.

This invention pertains to an

improvement of said idea by conveniently placing in the water?s path

a device to produce whirling motions in the fluid.

The simple emplacement in the outer

zone of the device will create turbulence between the center and the

perimeter, so as to generate a well-defined flow zone in the center

and layers of well-established stability from the perimeter inwards.

The emplaced devices are of the kind illustrated in Figure 1,

where we have an element (2) with its two ends bent (4)-(5) and

striations dug out at the back (6); this device, when inside the

tube (1) as seen in Figure 2, will meet the incoming flow and

twist it along the new path (3), so as to createa circular motion in

the liquid.

Figure 3 shows the device of

Figure 1 straightened out so as to show its true shape.

Figures 1-3

Austrian Patent

# 142,032

(June 11, 1935)

"Construction

for Fabricating Tap Water like that of Natural Springs"

by Viktor Schauberger

It is known that, to fabricate

mineral water through devices, without any unhygienic condition in

the pipes or through the mixing of salts and compressed gases under

pressure of at least 2-3 atmospheres, this is usually made under an

even higher pressure.

It is also known that to generate

soda water the water will be mechanically made to flow through

carbonic acid under a pressure of 12 atmospheres, so that the

corresponding enrichment in the forementioned cells make the water

"active". In other procedures, this is done through "cracking".

The creation of artificial mineral

water will also include carbonic acid under more or less great

pressure of at least 1 atmosphere, so that the salts will mix

evenly, as is done in several kinds of mineral water; and in other

kinds of waters there is a slight dissolution of carbonates (for

example, sodium bicarbonate) that also include carbonic acid,

obtaining from this a prickling taste. In the forementioned

procedures it is necessary, for producing a good mineral water, that

the ingredients not be in free form but in combination and in

relation so that the final product be as similar as possible to

natural spring water.

As shown in the Figure 1,

sterilized water flows through cold mercury light in tube (M) and

mixes with the diluted salts coming from (1). In container (C) the

mentioned salts are diluted in water and well mixed by revolving fan

(G). The mixture and kinds of salts direct themselves naturally

through the sterile water outlet, and do so with different and

permanent degrees of hardness.

On the other side, so that the

concentration is not too high, the artificially generated mineral

water?s hardness must not exceed factor 12 so that industry may not

be hindered by it; anyway, outgoing water needs for every 10 liters

output 1 liter of diluted salts in the following constituency and

proportions:

Sodium Chloride (NaCl), 0.02 gr

Magnesium Sulphate (MgSO4), 0.02 gr

Sodium Biphosphate (NaPh2), 0.02 gr

Potassium Nitrate (KNO3), 0.008 gr

Calcium Oxide (CaO), 0.2 gr

The kind and proportion of these

salts are the results of several hundreds of experiments. While the

calcium oxide dissolves itself in water, on the other hand the

calcium hydrate is very sensitive to the oxygen in the carbonic

acid, and thus is affected by it and the mercury light.

For the sake of regulating the liquid

flowing out of the container (C), this is inside at a constant

pressure of 0.1 atmosphere = 1 meter of acid water; the concentrated

diluted salts will fall dropping along the pipe (1) and when mixed

with the contents from (A) will flow into the apparatus (D) which

turns them into droplets, where they will jump from the outflow

holes of pipe (N) towards the walls of the apparatus (D); during the

process the water already processed through carbonic acid will flow

outside through the tube (K).

The droplets of both mixed liquids

fall downwards and mix in the way as happens in nature, where the

droplets of rain first lose their salts and diluted gases when

hitting the ground. This mixed water flows within and through the

tulip-glass device (E), where it always goes up in the outer tulip

glasses and down in the inner ones, so that it will pass into the

other following tulip-glass vessel after it has climbed into the

innermost one of the former stage and thus continues its flow. The

water makes a meandering motion to carry on the following indicated

goal.

The gas, especially carbonic acid,

collects itself in the upper portion of the tulips and will then,

through the corresponding growing pressure, flow through pneumatic

tube (R), in which fine nozzles is also injected water for flowing,

so that the carbonic acid that is not already combined with the

water will be later. On the axis of this device?s stages are placed

alternately gold and silver foils, isolated form each other; between

both metals there is an electric potential that creates a reduced

ionization in the flowing liquid.

In its further motion, water

penetrates into the main mixer (F), which is insulated against heat

and silvered within, and within which is located an upwardly

spiraling path which direction of winding goes against that of the

snail and is made out of wire mesh.

On the spiral?s surface are orderly

placed cooling spirals that take the temperature of water from 17

degrees C to 4 degrees C. The goal of this temperature fall is to

properly combine the chemical elements. The absorption of the gases

in water will be increased by the cooling, and otherwise makes

possible the combination and enrichment of free carbonic acid of the

resulting masses without the use of pressure.

The Ca(HCO3)2 presents a weak

exterior combination that the enrichment with the forementioned

carbonic acid had worked out, but the enrichment of Ca(HCO3)2 with

carbonic acid is possible only through cooling in water and the

maintenance of an even temperature.

The temperature of outflowing water

must not be over 20 degrees C and its final temperature (once it was

processed) should not be over 4 degrees C; it must also be taken

into consideration that the speed of flow must not be too fast to

allow the proper mixing of liquids; after leaving the container (F),

the liquid is made to flow through gold and silver foils until it

reaches vessel (I), which is divided into chambers (G) and (H).

First, the water that overflows from

(G) falls into chamber (H), and so on out of the device (Z).

By the treatment of water as

indicated, many reactions are produced; first of all, the water is

made wholly drinkable. It is also necessary to eliminate any

possible exposure to light during the process, for light falling on

the treated liquids produces a loss of quality in the final results.

Figure 1

Austrian Patent

#166,644

(August 25, 1950)

"Plow"

by Viktor Schauberger

It resulted from numerous experiments

that a better plowing of the soil can be achieved with

copper-covered plows instead of using plows made of iron or steel.

This difference becomes stronger when one notices that the speed of

plowing becomes faster and that the friction between the ground and

the corresponding portion of the plow is greater.

This effect of greater speed produces

the slow disintegration of the copper cover, and the minute copper

particles deposited in the soil produces a catalytic effect that in

turn generates better water retention in the ground and also a

further increase in the quality of plowing.

These findings were made when passing

a plow which body was either covered or entirely made of copper.

But as the building in whole of the

plow with copper is disadvantageous, it will be convenient to cover

those portions with copper layers in hardened condition, which can

be made through several different methods. The deposit of copper

particles under the ground does not break the magnetic permeability

of the soil, as does iron or steel.

Two embodiments are shown in the

illustrations. Figures 1 and 2 show a lateral view and

Figures 3 and 5 show a transverse cut, a

longitudinal cut, and one plowing protrusion.

In Figures 1 and 2 is

illustrated a plow with point (1) made of steel as usual, but it can

also be covered with the corresponding copper cover; this portion

cuts through the ground, generating friction in the process; another

is in the smaller portion (2), upon which upper portion there is

usually a small heap of sol because of pressure when the plow moves

forward. It will be furnished with an endtail (3), also made of

copper, that will create a "screwing" motion in the soil by means of

sunk "screw" (4) located at portion (2). In order to make the whole

of this latter portion hard enough, it must be hammered during

construction.

The plowing protrusion (5),

corresponding to Figure 3 to 5, is made with a

backward open sheet (6) of copper; to fasten upon the protrusion the

usual arrow, we use lock (7) of protrusion (5) placed at a high

location and which is furnished with the corresponding key; here it

is also convenient to place the copper cover by hammering upon the

protrusion.

Figures 1-5

Austrian Patent

# 196,680

(March 25, 1958)

"Tubing for

Flowing & Gaseous Media"

by Viktor Schauberger

Already there are many propositions

for the conduction of fluid or gaseous media so as to eliminate

losses in pressure or speed of motion. Thus it is to prevent the

formation of air vesicles that it is suggested an increase in

resistance to flow as in British Patent #409,528, wherein is

described a tubing that has spirals engraved within and which area

in transverse section will be limited by two segments of circle

arcs.

From the British Patent #28,543

(1913) comes a tube which transverse section is egg-shaped, which is

furnished with guiding means to prevent the formation of water

whirls. In the US Patent #1,655,197, as in the Swiss Patent

#126,637, are indicated either conical or cylindrical tubes for the

sake of limiting the sedimentation where the tube serves as axis for

the dragging of sediments; this is further explained in Austrian

Patent #28,099 exhibiting indented piping.

This invention pertains to a tube for

flowing and gaseous media to prevent the formation of incrustations

and to hinder the loss of flow speed, which cross-section is made

out of several circle arcs, being the tube wound helically and

having its cross-section an egg-shape with an indentation (Figure

1), and helically wound (Figures 2-4) around different

forms.

With the aid of such tubing, the

reduction in friction losses and the hindrance of incrustations

within the pipe will follow; for the sake of increasing the former

properties it is convenient to wrap the tubing and its cover around

circular conduits. This axis of winding will also serve as axis for

dragging along sedimentary materials, and will also contribute to

reduce in scale the cross-section of the tube for winding.

Figure 1 shows the

cross-section of the proposed tubing, and Figures 2-4 the

different ways of winding the conduit.

In Figure 1 is shown the

employed egg-shape with an indentation close to the (---) line; the

winding of the conduit can be made as shown in Figures 2-4

around an imaginary solid or in the form of a circular spiral, or in

any other convenient way.

In the winding or in its cover, in

Figures 3 and 4, we can scale the shape of the winding to

make it turn around those imaginary bodies or in a straight line.

One can also arrange the tubing, in relation to the fluids

conducted, to make the axis of winding equal to the one of dragging

sedimentary materials to reduce incrustations and losses in flow

speed.

Figures 1-4

Austrian Patent # 145,141

Air Turbine

(4-10-1936)

Viktor Schauberger

It is known that impellers can be

caused to rotate by moving air. It is equally known that an air

current can be generated through evacuation. The present invention,

however, makes use of mechanical and physical forces.

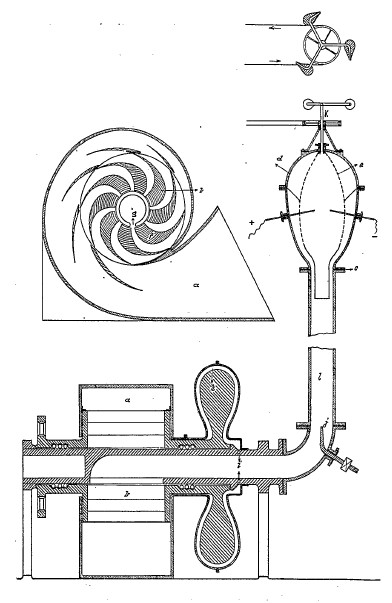

In the accompanying diagram (see

fig. 19), the object of the invention is portrayed in Sections

A-A and B-B. A snailshell-shaped housing a in which the impeller

b is mounted is connected to a double-spiral pipe c by means of

a hollow shaft d. The double-spiral pipe c is joined to an

egg-shaped, hollow body e at f, which is divided into two spaces

by means of a wire mesh g. In the inner chamber of e gas-burners

or electric arc-throwers are incorporated that combust the

inflowing gas at about 2,000?C (3,632?F). The inner chamber is

connected to an exhauster via a heatable double-spiral pipe h.

To this exhauster, streamlined, egg-shaped nozzles i are

attached and the whole arrangement is activated by an external

force.

The impeller incorporated

inside the snailshell housing is constructed in such a way

that fresh air can only enter the hollow shaft d when the

impeller blade k passes over the slot j incorporated in the

hollow shaft. The flywheel l, whose cross-sections are

egg-shaped and which is mounted on the hollow shaft d, is

installed in an externally airtight housing m. The air

present in the hollow space n is sucked out through a

connecting passage o, so that in the highly rarefied space n

the flywheel is offered very little resistance to rotation.

To maintain the combustion process, a combustible gas is

introduced at p. The double-spiral pipe c mentioned at the

beginning has been granted an Austrian patent, No. 138296.

This pipe consists of an external pipe made of wooden staves

and an asbestos sleeve. Within the latter there is a metal

sleeve, which has wood-shaving-like metal elements bent out

from the periphery, whose axis is inclined towards the

pipe-axis at an angle of 30? to 45?. [3] [3: consult patent

138296] These metal elements are aligned along several

spiral pathways. The peripheral air-masses will thus be

forced to describe a path corresponding to a spiral within a

spiral.

The inner metal sleeve

is heated electrically. In addition, the heat arising

from friction on the outer walls leads to the warming of

the outer air-masses, through which in particular all

the oxygen contained in the air expands, concentrates

itself at the pipe-walls, becoming even warmer on its

multi-spiral path along the pipe-walls. The remaining

gases contained in the air pass down the centre of the

pipe and rise through the agency of the gas introduced

at p. Because the warmer and therefore more aggressive

oxygen brushes along the outer pipe-walls and the colder

residual components of the air flow through the inner

region of the pipe, inner tensions arise between the

materials due to the temperature differences obtaining,

which become more pronounced the longer the distance

travelled, until interactions ultimately occur. These

interactions proceed in the form of small explosions and

assist the reaction that takes place through the

combustion of the highly energised gases within the

egg-shaped safety mesh g.

In the egg-shaped

body e a sieve (safety mesh) g is incorporated,

outside of which the separated oxygen mentioned

earlier accumulates, passes through the sieve into

the centre, wherein, with the aid of the electric or

gas arcs, it contributes to the almost complete

combustion of the centrally conducted combustible

gases. As a result a much greater vacuum evolves

than has hitherto been achieved using currently

known methods. At the same time the exhaust gases

are reduced to a minimum and extracted mechanically

via h and i. Through the creation of the vacuum in e,

the air will be sucked in with even greater force,

setting the impeller in motion in the process.

Claims

1. The

air-turbine is characterised by the fact

that the air-masses in a doublespiral pipe

can be so strongly moved, that due to

frictional heat and externally supplied heat

between the peripheral air-masses and those

streaming down the pipe-axis, differences in

temperature arise, which lead to cold

interactions in the air flowing through the

double-spiral pipe, whose end-product is an

almost total vacuum.

2. In

accordance with Claim 1 the air-turbine

is further characterised by the complete

combustion that takes place in a

partitioned chamber by means of a safety

mesh having a pipe-shaped extension

towards its base.

3.

In accordance with Claims 1 & 2, the

air-turbine is characterised by the

fact that the attached flywheel is

caused to rotate in a rarefied space.

4. In accordance with Claims

1-3, the air-turbine is

characterised by the fact that

the supply of air takes place

pulsatingly through a slot in

the hollow shaft.

5. In

accordance with Claims 1-3,

the air-turbine is

characterised by the fact

that the discharge of

exhaust gases takes place by

means of a heated pipe in

which a temperature higher

than that of the exhaust

gases prevails.

Classification: - international: B01D53/86; B01J19/24; B01D53/86;

B01J19/24; - European: B01D53/86; B01J19/24B